How Multi-Zone Sourcing Can Save Your Supply Chain – And Your Sanity

Let’s face it, the past few years have been a crash course in supply chain fragility. If you’re a CEO or senior manager in manufacturing, you've...

All tasks in Shop Floor Management -

digitally supported with the functions of ValueStreamer®.

ValueStreamer® as a leadership tool supports the continuous improvement of processes and the optimization of collaboration.

Optimize processes in all areas of your business with digital Shop Floor Management. Learn more about the use cases.

8 min read

Dr. Andreas Romberg

:

Nov 13, 2023 1:54:03 PM

Dr. Andreas Romberg

:

Nov 13, 2023 1:54:03 PM

TABLE OF CONTENTS

Summary

Digital Shop Floor Management (dSFM) is characterized by the fact that the basic SFM method remains the same, but the tools and instruments are completely digitalized or digitally supported.

With the help of dSFM, companies can further optimize their processes across different departments and locations.

In this blog article, you can find everything you need to know about digital Shop Floor Management, its benefits and how you can successfully digitalize your analog SFM.

Digital Shop Floor Management (dSFM) can be described quite well with the following sentence:

"The method or management framework of Shop Floor Management remains the same, but the tools for SFM change - they are digitalized or digitally supported."

The digitalization of the tools massively supports the method and thus the acting managers and employees. Efficiency in the application of SFM is no longer only promoted locally, but also in distributed or global value chains - even beyond production. The aim is to further optimize processes with the help of SFM and digitalization.

It is important to emphasize at this point:

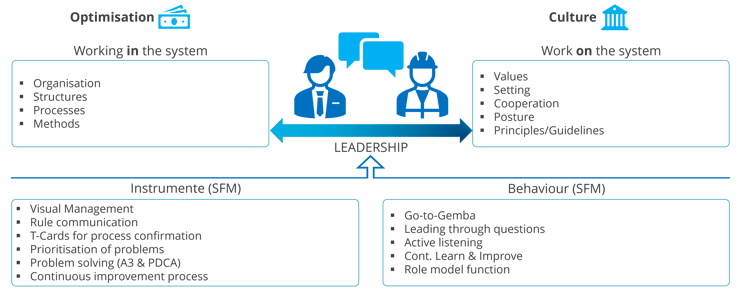

The following graphic explains what constitutes digital SFM and how it differs from traditional, analog Shop Floor Management.

Source: Staufen.ValueStreamer GmbH

The methodical part or the management framework of Shop Floor Management remains unchanged, namely (see upper part of the figure):

This also means that the classic stand-ups or morning rounds are replaced by dSFM. In concrete terms, this means that the joint face-to-face meetings at the respective locations involved will remain, but will take place in front of the digital board.

What will change significantly, however, is the targeted use of software to digitalize the instruments and support behavior.

1. Digitalization of the SFM instruments

| Instrument | Digitalization |

|

Visual |

Whiteboards/ paper boards are being replaced by screens/digital Shop Floor Boards. |

|

Digital data preparation for digital dashboards; |

|

|

Recurring |

Digital support for moderators in recurring communication. |

|

Enabling international, cross-location SFM meetings (e.g. COO with his location managers). |

|

|

T-Cards for Process Confirmation |

Digital ticket or Kanban boards for task control within the work system, including recurring tasks (e.g. T-cards). |

|

Prioritization of |

Digital and automated presentation as well as prioritization of problems for processing in deviation management, e.g. depending on the impact on the work system. |

|

Problem-solving |

Digital support and guidance through the fault elimination process (PDCA method) or through structured problem solving (A3 mehtod). |

|

Continuous |

Digital control and tracking of continuous improvement processes and associated task tickets in the work system. |

2. Support of the behavior

...to create commitment in management.

In summary, it can be said that digital Shop Floor Management helps to further improve efficiency, quality, flexibility, and agility in work systems (production, logistics or even in office areas).

This can lead to decisive competitive advantages for companies - from significantly increased customer satisfaction to cost benefits.

The benefits of dSFM result from extending the advantages of classic Shop Floor Management to include the advantages of digitalization. This enables companies to record, process and provide data more easily.

The concrete benefits result from

As a result, companies gain better control over their processes, react more quickly to changes and continuously improve the efficiency and quality of their work systems. It also enables them to make faster, better and fact-based decisions.

This is particularly advantageous in the context of global work systems, as conventional or analog Shop Floor Management clearly reaches its limits here. Collaboration is increasingly taking place across locations and more and more in networks. It is simply not possible to transfer a collection of analog data (e.g. on a paper board) to another location.

Why should Shop Floor Management be digitalized?

To answer this question, we will first assume the classic application of SFM in the operational area (e.g. production, assembly, supply chain management, logistics, etc.). In this context, the following reasons for digitalization arise:

|

Reason |

Description |

|

Reducing effort |

Automated data collection, evaluation and provision/visualization through data integration from third-party systems eliminates repetitive, manual activities. This leads to considerable increases in efficiency. Experience has shown that this saves around 1,400 hours per year in a work system with around 150 employees and 3-level cascades. |

|

Flexible data analyses are possible without a great deal of manual effort. |

|

|

Increasing |

By connecting to third-party systems with automatic data integration, data from different software systems is bundled in one place. Data is distributed and visualized globally in real-time via the dSFM system, which acts as a central information platform, ensures end-to-end transparency, and serves as a basis for performance improvement. |

|

Real-time data integration from third-party systems ensures higher data quality and up-to-dateness. This enables faster and better decisions to be made with less risk potential. |

|

|

The integrated, digital deviation management enables transparent and centralized tracking of all measures from improvement actions, error correction measures (PDCA) and problem-solving (A3). |

|

|

Creating |

Global company standards for Shop Floor Management can be defined, established and adapted quickly and easily (e.g. KPIs, list elements, problem-solving and error correction processes, etc.). |

|

With regard to the processes, digital process twins (templates) of the processes and projects to be controlled (order processing, ramp-up management, product development, quotation preparation, etc.) should also be mentioned here. |

|

|

Simplifying & |

The digital implementation of standardized SFM instruments is faster, more cost-efficient, and less complicated than the analog version - especially in global value chains. |

|

Sustainability & |

Travel times and costs are reduced. |

|

Less paper consumption and cost savings due to the use of a screen compared to traditional visualization methods (whiteboard). |

|

|

Optimizing |

Mobile accessibility enables efficient, global communication and facilitates remote leadership. |

|

The visualization of positive results, such as team success based on the development of KPIs, can increase employee motivation (gamification effect) |

If the focus is extended beyond the operational areas to the processes and line functions of the entire company, there are further, very worthwhile benefits of so called "Office Floor Management":

In office areas, digital Shop Floor Management leads to:

dSFM also contributes to increasing the robustness and resilience of work systems against the backdrop of an ever-increasing need for companies to adapt to their environment.

1. Increased efficiency

2. Reduced process runtimes

3. Continuous Improvement

4. Increased flexibility and adaptability Flexibilität und Anpassungsfähigkeit

5. Better collaboration and communication

6. Simplified documentation and traceability

1. Create management attention

Establish management attention with the highest-ranking manager in the SFM cascade. This person is the sponsor of the dSFM project and must be convinced of it.

2. Create a consistent basis for the understanding of SFM methodology

Everyone is on the same level in terms of understanding and applying the SFM methodology.

You can achieve this by taking these 5 steps:

3. Define the project team, roles and, communication in the project

Finally, roles must be assigned, and all stakeholders informed.

We come across digital in-house solutions with tools such as Office 365, Excel Shop Floor Boards or other no-code or low-code solutions as well as BI tools in our consulting and implementation practice.

We have great respect for the ideas, the work and the efforts that are sometimes put into these solutions and the things that are sometimes possible.

However, when comparing these in-house solutions with the digital Shop Floor Management tools available on the market, it is clear that the snags should not be underestimated:

Transparency-creating tools, such as BI or process mining tools etc., are far from being SFM tools, because:

For the reasons mentioned above, the combination of SFM tools with BI and/or process mining tools would create perfect synergies in this context.

Let’s face it, the past few years have been a crash course in supply chain fragility. If you’re a CEO or senior manager in manufacturing, you've...

What’s Going Wrong, and What You Can Do About It If you manage a mid-level manufacturing company, you know the pressure of meeting yearly goals. But...

When we think of Halloween, images of haunted houses, spooky masks and eerie fog may come to mind. But what if we told you that these elements are...

More efficiency through digital transformation in value stream and shop floor management

Effective Shop Floor Management (SFM) is a critical success factor for any production plant as well as in indirect areas e.g., the development...