How Multi-Zone Sourcing Can Save Your Supply Chain – And Your Sanity

Let’s face it, the past few years have been a crash course in supply chain fragility. If you’re a CEO or senior manager in manufacturing, you've...

All tasks in Shop Floor Management -

digitally supported with the functions of ValueStreamer®.

ValueStreamer® as a leadership tool supports the continuous improvement of processes and the optimization of collaboration.

Optimize processes in all areas of your business with digital Shop Floor Management. Learn more about the use cases.

Summary

Operational Excellence (OPEX) is a must for companies that want to remain successful in today's volatile business world.

It is about far more than just lean processes.

Organizations must leverage all optimization potential along their entire value chain in order to respond flexibly to external events, meet customer needs and remain competitive.

However, the successful implementation of OPEX is not a one-off affair. Rather, it is a fundamental transformation of the prevailing ways of thinking and working.

In this blog post, we will give you a comprehensive overview of the complex topic of operational excellence. Among other things, we will provide practical tips on how you can achieve OPEX effectively - and how digitalization can support you in doing so.

Operational Excellence (OPEX) is a holistic, strategic management approach that aims to continuously improve the overall performance of a company towards excellence in efficiency, quality, customer satisfaction and processes.

This is achieved by permanently optimizing processes, structures, methods, etc. along the value chain, reducing waste and promoting cooperation within the organization.

The result is excellent processes that are robust and adaptable. These increase productivity, reduce costs, and contribute to remaining competitive and achieving long-term corporate success.

Areas, that operational excellence covers; Source: Staufen.ValueStreamer GmbH

Many different methods and approaches can contribute to achieving operational excellence. These include Lean Management, CIP, Six Sigma, Total Quality Management, Kaizen and agile methods.

A wide range of methods can therefore be used for implementation.

The most important ones are:

Lean Management is a management philosophy that aims to minimize waste in processes by eliminating non-value-adding activities. This includes principles such as continuous improvement, just-in-time production and error prevention.

CIP is usually mentioned/applied in the context of Lean Management and is generally a key principle of operational excellence. It encourages employees at all levels to continuously look for ways to improve processes. The difference between CIP and OPEX is that CIP only focuses on processes. Operational Excellence refers to the entire company.

Six Sigma is a data-driven statistical methodology. The aim is to improve the quality of processes by reducing variations. Six Sigma focuses on the identification and elimination of defects and undesirable deviations.

TQM is a comprehensive approach to improving quality and performance. The entire organization, its processes, products and services, is included in the process of continuous improvement.

Agile methods have become increasingly important in recent years - even beyond their pure application in software development.

Agility is also becoming increasingly important in other areas outside of development. It is more than just a collection of methods. Rather, it is a mindset and an attitude as part of a corporate culture that strongly supports iterative development, close collaboration, self-control and rapid adaptation to changing requirements.

At first glance, the methods and approaches appear very similar; there are also frequent overlaps in practice. However, different OPEX standards are applied in some cases, which can be broken down into specific actions, processes and tools. These vary depending on the industry, company size and objectives. Ultimately, they all have one thing in common: achieving top performance through process optimization.

Especially in recent years, markets have changed as a result of globalization. Organizations have a much larger number of competitors. It is no longer enough to simply sell good products or services. In order to remain competitive under these circumstances, companies must scrutinize the current situation on a daily basis to see what can be done even better. Operational excellence serves to bring out the full potential of a company.

By identifying and eliminating waste (muda), bottlenecks and inefficient processes, an organization strives for optimal use of resources, time and energy.

By avoiding bottlenecks and waste in processes, smart collaboration approaches (such as "Performance-U") can significantly reduce process lead times. At the same time, the throughput of projects/tasks is increased with the same team.

By taking a broad approach to reducing waste and inefficient practices, companies can reduce costs and increase profitability. Examples include:

Quality/Non-quality costs:

here the continuous improvement approach aims to increase product/service quality and minimize defects or errors.

Increasing productivity:

focuses on avoiding waste in processes as well as in cooperation at interfaces.

Increasing sustainability:

focuses on optimization in energy consumption and thus the CO2 footprint.

Degression of fixed costs:

focuses on smart collaboration, particularly in cross-functional processes. In addition to a reduction in process lead times, this also promotes an increase in the throughput of projects and tasks with the same organizational size.

The focus is on meeting customer needs and the associated processes for providing products as well as services

Companies with operational excellence have introduced and implemented the principles of Lean Management as a basis. Building on this, agility enables these companies and their excellent processes to adapt quickly to changing market conditions and customer requirements.

Involving employees at all levels in the continuous improvement process can lead to a positive work culture, higher engagement and improvement contributions across the workforce.

Operational Excellence is not a one-off effort.

Rather, it is a basic attitude or mindset within the organization that must be anchored in the corporate culture and fundamental working methods.

Successful implementation comprises the following elements:

The seven elements of a successful OPEX implementation; Source: Staufen.ValueStreamer GmbH

1. Preparation & planning

Analyze your current business processes in detail and identify processes with potential for optimization.

Define a clear target picture that is in line with the overriding goals of the organization.

Select the optimization method that meets your requirements.

Plan the procedure and start in phases within a pilot area - the larger the organization, the more challenging is a simultaneous roll-out across all areas.

2. Training of managers

Ensure that the managers adapt to the new role and gradually accept it.

They take on the role of:

3. Empowerment of employees

Enable your employees to learn through self-knowledge.

This takes place in special learning situations in which the employees independently apply the principles and tools of the selected optimization methods. At the same time, they interact with managers, receive feedback and are being coached.

4. Measurement of progress

Continuously track progress in the pilot area. As soon as initial successes are achieved, the OPEX program can be extended to the entire company in clearly structured phases.

5. Involve all stakeholders

Ensure that knowledge snowballs throughout the entire organization - both broadly and deeply - so that all employees are involved in the implementation process.

6. Continuous optimization

Record the progress and results of the OPEX implementation at regular intervals in order to continuously improve the processes. This ensures that you achieve optimal results and the defined objectives.

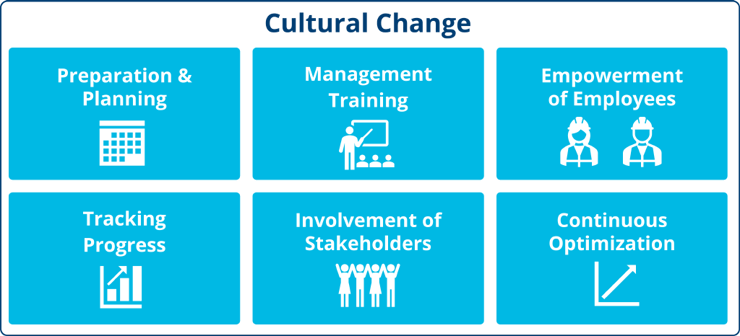

7. Cultural change

When implemented, OPEX is a mindset or cultural element.

Therefore, one of the most important and critical aspects for the effective implementation of Operational Excellence is the cultural change within the entire organization.

A culture of continuous improvement has to be established. This requires a far-reaching, long-term transformation of the attitude, philosophy and methods used by managers as well as employees. New behavioural and coping mechanisms must be learned and internalized.

As a rule, this process requires external support to ensure an objective perspective and support the transition.

The use of digital tools to improve operational processes is proving to be extremely useful in an increasingly complex working environment.

This is because digital tools enable organizations to effectively eliminate waste and inefficiency. At the same time, they promote agility, improved communication and optimal collaboration.

When implementing OPEX methods, the supportive use of software makes implementation much easier, because it starts exactly where the analog methods reach their limits.

However, simply digitizing the methodology is not enough - it is much more important that the corresponding mindset is present.

On the one hand, the supportive use of software makes it possible to standardize processes, improve quality and increase productivity.

On the other hand, digital tools can help to anchor the strategic mindset of OPEX in the corporate culture.

For example, by digitally supporting a functioning leadership framework that focuses on continuous improvement and the consistent pursuit of excellence. This would be possible with a software for digital Shop Floor Management in a lean context.

1. Elimination of inefficient processes

The use of software makes it possible to overcome data silos and gaps. This can save up to 100% manual effort.

Updating work and process instructions at the push of a button also eliminates processes that are considered wasteful reagrding to Lean management.

2. Facilitation of collaboration, communication & employee engagement

In addition to processes, OPEX focuses in particular on the people behind them. Digital tools should therefore be used to support employees and enable optimal organization of collaboration.

The software should create standards, guide employees through processes and facilitate communication. The active contribution of knowledge or the guided but independent solving of problems increases employee satisfaction, which has a positive effect on productivity.

3. Reduction of error rate

Historical knowledge, such as functioning problem-solving approaches, meets real-time data. This combination ensures comprehensive transparency.

Dashboards, which are easily accessible and understandable for all those involved, provide a real-time overview of KPIs, deviations or the current project status. As a result, errors or bottlenecks are identified immediately and can be rectified with just a few clicks using the stored knowledge.

This forms the basis for quality improvements and CIP.

Operational excellence and digitalization are closely linked and reinforce each other.

Companies that implement both concepts not only streamline their processes. The ability to make data-based decisions in real time puts these companies in a better position to remain competitive and achieve long-term success.

Would you like to start implementing Operational Excellence?

With our software for digital Shop Floor Management, we support you in optimizing your processes and anchoring the OPEX mindset in your corporate culture based on our leadership approach.

Get in touch with us now!

Let’s face it, the past few years have been a crash course in supply chain fragility. If you’re a CEO or senior manager in manufacturing, you've...

What’s Going Wrong, and What You Can Do About It If you manage a mid-level manufacturing company, you know the pressure of meeting yearly goals. But...

When we think of Halloween, images of haunted houses, spooky masks and eerie fog may come to mind. But what if we told you that these elements are...

More efficiency through digital transformation in value stream and shop floor management

Is lean management still up to date? We've been hearing more and more lately: Lean is over! We have been in the age of beyond lean for a long time!

Definition of Lean Management Lean management is a management framework that aims to continuously improve efficiency and productivity in all...